Exploring the detailed production process behind Rubber Keypads and why they matter

The Relevance of Rubber Keypads: How They Improve Individual Experience Throughout Different Industries

Rubber keypads are indispensable elements in various sectors, contributing significantly to customer experience. Their responsive feedback supplies a sense of control and convenience, while their longevity assurances lengthened use. The adjustable nature of these keypads enables aesthetic enhancements that deal with customer choices. Recognizing their applications discloses how these features equate into customer contentment. What details benefits do rubber keypads offer each sector, and how do they foster brand loyalty?

Understanding Rubber Keypads and Their Capability

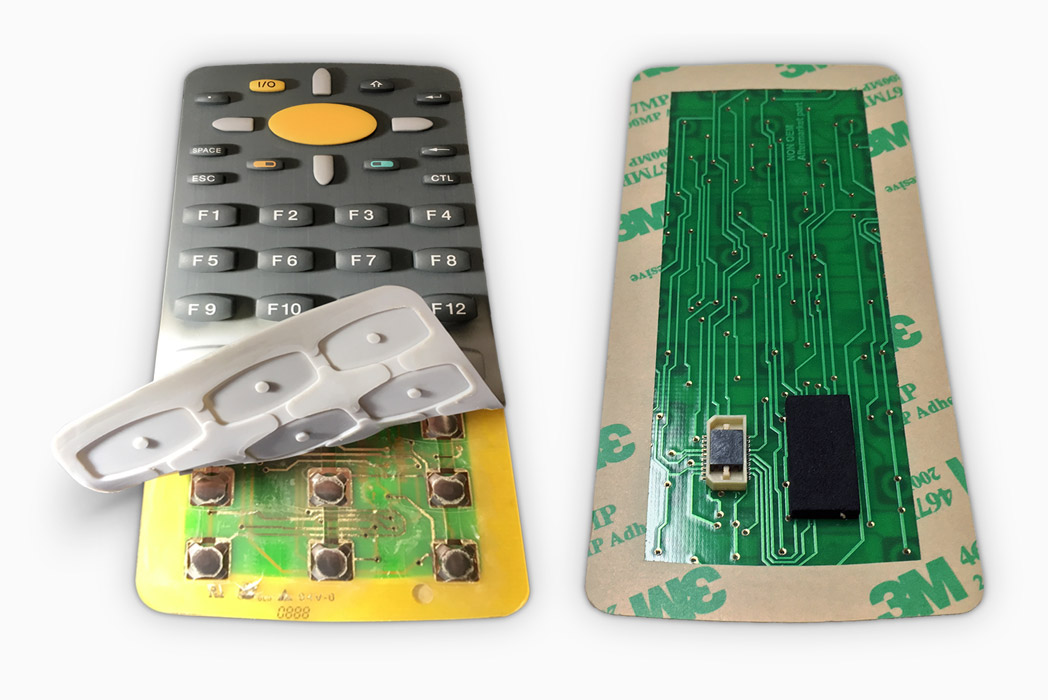

Rubber keypads, integral parts in lots of digital devices, offer as the primary interface for user communication. Consisted of elastomer materials, these keypads supply tactile comments and durability, making them suitable for different applications. They include several layers, consisting of a conductive layer that completes the circuit upon crucial activation, making certain reputable performance. The layout often features raised buttons, which promote ease of use and ease of access, particularly in settings where customers could wear gloves or have limited mastery.

Rubber keypads are immune to dampness, dirt, and chemicals, boosting their long life and reliability in varied setups. Their personalization possible enables producers to produce special layouts and layouts customized to details customer requirements. This performance not only enhances individual experience however additionally permits smooth combination across gadgets, strengthening the importance of rubber keypads in modern innovation. On the whole, their convenience and functionality make them important elements in the electronic landscape.

The Function of Rubber Keypads in Consumer Electronic Devices

While lots of parts add to the functionality of customer electronic devices, rubber keypads play an important role in enhancing individual interaction. These keypads are typically discovered in tools such as remotes, smartphones, and video gaming controllers, supplying tactile comments that boosts the general customer experience. The soft, flexible nature of rubber keypads permits comfortable pressing, making them suitable for regular usage.

On top of that, their longevity and resistance to use warranty durability, an important element for tools based on daily handling. Their style can be personalized to fit numerous sizes and shapes, permitting manufacturers to create visually pleasing items that are additionally useful. Rubber keypads typically include water and dust resistance, making them suitable for varied atmospheres. Eventually, the combination of rubber keypads in consumer electronic devices not just simplifies communications but additionally contributes to the access and usability of modern-day innovation.

Enhancing Individual Experience in Medical Tools With Rubber Keypads

Rubber keypads can especially enhance user experience in medical devices with their ergonomic layout, which promotes convenience during long term use. Additionally, these keypads use advantages in hygiene and sanitation, making them suitable for settings where sanitation is extremely important. The assimilation of rubber keypads in medical modern technology presents a chance to improve both usability and safety and security for medical care specialists and individuals alike.

Ergonomic Design Benefits

The combination of ergonomic style in clinical tools significantly boosts user experience, especially via the usage of rubber keypads. These keypads are crafted to adapt the natural shapes of the hand, decreasing strain during prolonged usage. Their tactile responses provides users with a rewarding feedback, promoting precise input in high-pressure scenarios. Rubber keypads frequently include bigger, well-spaced tricks that decrease the likelihood of errors, which is crucial in clinical settings where precision is critical. Furthermore, the gentleness of the rubber product allows for comfy operation, particularly for customers that might have dexterity obstacles. Generally, the ergonomic layout of rubber keypads significantly adds to an extra straightforward and user-friendly experience in clinical gadgets.

Hygiene and Sanitation

The Effect of Rubber Keypads on Automotive Controls

Rubber keypads play a crucial function in automobile controls by using enhanced toughness and reliability, important for cars that endure numerous environmental problems. In addition, their design adds to boosted ergonomics and functionality, allowing chauffeurs to interact with controls much more easily and successfully. The combination of rubber keypads can considerably influence the general company website customer experience in automobile settings.

Improved Durability and Dependability

While several components in automotive design face the tensions of day-to-day usage, rubber keypads stick out for their outstanding toughness and dependability. These keypads are crafted to hold up against extreme temperatures, dampness, and mechanical wear, making them suitable for various vehicle applications. Their resistance to ecological variables warranties consistent performance, even in severe conditions. Additionally, rubber keypads are less vulnerable to breaking or fading compared to conventional materials, which boosts their longevity. This sturdiness is necessary for automotive controls, where performance directly influences security and individual contentment. By preserving a reliable user interface with time, rubber keypads contribute significantly to the total reliability of auto systems, enabling suppliers to offer a trustworthy experience for guests and drivers alike.

Boosted Comfort Designs and Usability

A considerable advantage of rubber keypads in auto controls is their contribution to enhanced comfort designs and usability. These keypads are created to fit easily within the vehicle driver's reach, assuring that necessary functions can be accessed easily and intuitively. The responsive feedback given by rubber products enhances the customer experience, allowing chauffeurs to operate controls without diverting their focus from the roadway. In addition, the non-slip surface of rubber keypads assures a safe and secure hold, even in unfavorable problems. This design factor to consider reduces the danger of unintended activation, additional promoting security. Rubber Keypads. Finally, rubber keypads improve the functional designs of automobile controls, fostering an extra easy to use environment that inevitably adds to more secure driving experiences

Sturdiness and Environmental Resistance of Rubber Keypads

Keypads made from rubber are renowned for their impressive longevity and durability in numerous ecological problems. These keypads are designed to stand up to extreme temperature levels, moisture, and exposure to UV light, making them an ideal selection for commercial and exterior applications. Their intrinsic versatility permits them to soak up effects and shocks, minimizing the risk of damages from unintended decreases or rough handling. In addition, rubber keypads are immune to oils and chemicals, making sure long life also in severe working settings. This sturdiness translates right into reduced maintenance costs and fewer replacements, improving general customer experience. Their ability to retain performance despite direct exposure to dirt and debris makes them suitable for a myriad of industries, consisting of auto, clinical, and consumer electronic devices. The durable nature of rubber keypads plays an important duty in making sure integrity and performance, ultimately contributing to individual contentment throughout different sectors.

Ergonomic and visual Factors to consider in Rubber Keypad Style

The resilience and environmental resistance of rubber keypads provide a solid structure for their design, however functional designs and aesthetics additionally greatly influence user experience. The aesthetic allure of a rubber keypad can especially affect customer engagement; colors, designs, and appearances are very carefully considered to line up with brand name identification and customer choices. A thoughtfully developed keypad not only attracts individuals yet also enhances functionality via instinctive layout.

Comfort designs plays a vital duty also, as the tactile action and crucial spacing need to accommodate diverse user needs. Convenience during long term usage is crucial, triggering developers to concentrate on the shape, dimension, and placement of keys. Attributes like elevated secrets or contouring can improve functionality, reducing the threat of stress or pain. Eventually, a balance in between aesthetic charm and ergonomic performance assurances that rubber keypads contribute positively to site web customer complete satisfaction throughout different applications and industries.

Regularly Asked Concerns

What Materials Are Typically Made Use Of in Rubber Keypad Production?

Usual products used in rubber keypad production consist of silicone, polyurethane, and polycarbonate elastomers. These materials provide durability, flexibility, and responsive feedback, making them suitable for numerous applications in electronic tools and commercial devices.

How Do Rubber Keypads Contrast to Various Other Input Devices?

Rubber keypads provide toughness and tactile comments, distinguishing them from touchscreens and mechanical switches. They offer a trusted, weather-resistant news input option, commonly favored in industrial settings, while other gadgets may do not have similar resilience and individual comfort.

Are Rubber Keypads Customizable for Details Applications?

Yes, rubber keypads can be tailored for certain applications. Producers often supply various colors, forms, and tactile responses alternatives, enabling individuals to customize the keypads to match their visual and functional needs efficiently.

What Are Typical Issues With Rubber Keypads With Time?

Common concerns with rubber keypads with time include wear and tear, fading of icons, minimized tactile feedback, and degradation as a result of environmental variables such as moisture, temperature level fluctuations, and exposure to chemicals, affecting their efficiency and resilience.

Just How Are Rubber Keypads Tested for Quality Control?

Rubber keypads undergo rigorous testing for high quality guarantee, including longevity assessments, tactile responses analyses, and ecological resistance checks. These tests guarantee performance user, durability, and consistency fulfillment throughout different applications and markets, maintaining high requirements.

Rubber keypads are integral components in various sectors, adding significantly to customer experience. While numerous components add to the capability of customer electronics, rubber keypads play an important role in enhancing customer communication. Rubber keypads can especially boost customer experience in medical devices through their ergonomic design, which promotes comfort during prolonged usage. The assimilation of ergonomic design in medical gadgets considerably boosts individual experience, specifically through the use of rubber keypads. The resilience and ecological resistance of rubber keypads offer a solid foundation for their layout, however looks and functional designs likewise substantially influence customer experience.