How to Improve Your Projects With Woodworking Machinery Products

Discover the Crucial Woodworking Equipment That Every Craftsman Needs for Precision and Efficiency

In the domain of woodworking, the best machinery is important for attaining both precision and performance. Craftsmen count on vital tools like the table saw and miter saw to implement clean cuts. Band saws include convenience, while planers and routers fine-tune information and surfaces. Each machine plays a vital duty in the workshop. Comprehending their features can considerably improve a craftsman's ability. Yet, the trip into woodworking machinery does not stop here.

Table Saw: The Heart of Every Workshop

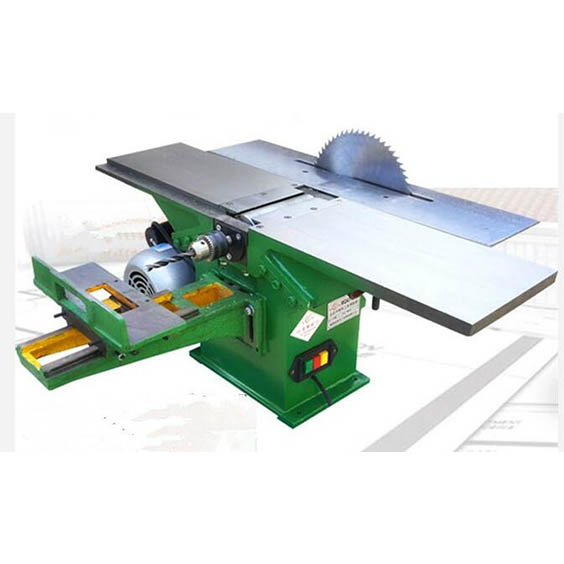

The table saw stands as the foundation of any type of woodworking workshop, embodying both accuracy and convenience. This vital machine allows craftsmen to make straight cuts with amazing precision, forming the basis for different tasks. Equipped with a circular blade placed on an arbor, the table saw allows individuals to readjust the deepness and angle of cuts, accommodating different products and thicknesses.

Its robust style supports large workpieces, making it perfect for ripping lumber and cross-cutting panels. Furthermore, the table saw commonly includes a fencing system, guaranteeing straight, repeatable cuts, which is vital for attaining uniform dimensions. Security functions, such as blade guards and riving knives, enhance the overall user experience, reducing the danger of crashes.

In significance, the table saw is not just a device; it is the heart of the workshop, empowering craftsmen to bring their visions to life with skill and accuracy.

Miter Saw: Accuracy Angles Made Easy

Miter saws provide craftsmen with the capability to make exact angled cuts effortlessly, a vital facet for lots of woodworking tasks. These devices are specifically favored for their accuracy in crosscuts and miter cuts, enabling woodworkers to achieve perfect angles rapidly. With adjustable setups, miter saws fit different degrees, enabling the development of elaborate layouts and exact joints for frames, moldings, and furnishings.

A lot of miter saws come equipped with a durable blade that ensures clean cuts, reducing the requirement for extra sanding or finishing. The straightforward layout permits for quick arrangement and modifications, making it suitable for both novices and experienced specialists.

Furthermore, the portability of several designs improves their charm, allowing artisans to work on-site or in constrained spaces. Overall, a miter saw is an essential device in any type of woodworking collection, offering the precision and effectiveness required for high-grade craftsmanship.

Band Saw: Versatility for Numerous Cuts

The band saw stands apart in woodworking for its exceptional flexibility, accommodating various cutting techniques. This area will explore the different types of band saws available, highlight their vital features, and offer crucial upkeep ideas for peak performance. Understanding these elements will make it possible for artisans to take full advantage of the performance of their band saws in diverse projects.

Types of Band Saws

Band saws are a staple in woodworking, providing an amazing variety of cutting capabilities that deal with numerous tasks. There are a number of kinds of band saws, each made for certain tasks. The vertical band saw is excellent for intricate cuts and resawing, enabling woodworkers to produce precise joints and curved shapes. In contrast, the straight band saw excels in reducing bigger items of material, making it suitable for industrial applications. Portable band saws offer versatility for on-site tasks, while the benchtop variation supplies a portable remedy for smaller sized workshops. Each kind offers a distinctive objective, ensuring that craftsmen can pick the right device for their particular cutting demands, boosting both accuracy and effectiveness in their woodworking undertakings.

Trick Includes Explained

Flexibility sticks out as a specifying characteristic of band saws, permitting woodworkers to take on a large variety of cutting jobs easily. These makers stand out in making straight cuts, curved cuts, and complex shapes, which makes them essential for numerous woodworking jobs. The flexible blade tension and variety of blade sizes improve their adaptability, enabling craftsmen to switch between reducing thick lumber and fragile veneer. Additionally, band saws typically include adjustable reducing elevations and sizes, giving flexibility in fitting various products. The capability to perform resawing more rises their utility, permitting customers to produce thinner boards from thicker stock. Overall, the band saw's combination of accuracy and adaptability makes it a vital device in any woodworker's workshop.

Upkeep Tips and Tricks

Maintaining a band saw is essential for making sure optimal performance and longevity. On a regular basis examining blade tension is vital, as incorrect tension can lead to inaccurate cuts and premature wear. On top of that, maintaining the blade tidy avoids resin accumulation, which can impact reducing performance. Lubricating the bearings and wheels decreases rubbing and extends the life expectancy of the saw. It is additionally crucial to check and align the blade guides consistently to maintain straight cuts. In addition, changing worn or damaged blades immediately enhances both safety and security and efficiency. Ensuring the band saw is saved in a dry atmosphere secures it from rust and rust, making it ready for precision cutting whenever needed. These upkeep techniques will certainly maintain a band saw running efficiently and effectively

Router: Detailing and shaping Woodwork

The router stands as a necessary device in the woodworking collection, recognized for its capability to form and information wood with accuracy. This versatile device uses a spinning bit to sculpt elaborate designs, grooves, and sides, making it indispensable for both ornamental and useful applications. Woodworkers utilize routers for tasks such as burrowing areas, producing profiles, and including decorative edges to furniture items.

With numerous accessories and bits readily available, the router can produce a range of results, from easy round-overs to intricate inlays. It accommodates both table-mounted and handheld setups, improving its use throughout different jobs. The speed and control provided by routers allow artisans to perform delicate collaborate with convenience, see post making them a favorite for intricate layouts. Inevitably, a router enhances the innovative possibilities in woodworking, enabling artisans to accomplish the thorough surfaces that boost their workmanship to the following level.

Planer: Achieving Smooth and Even Surface Areas

Woodworkers looking for to improve their tasks usually transform to the planer, an important device for attaining smooth and even surfaces. This machinery excels at getting rid of product from the surface of wood boards, guaranteeing a consistent density and removing flaws. By utilizing sharp blades and exact setups, the planer can change rough lumber into completely flat and refined surfaces, improving the total aesthetic and performance of the work surface.

Planers can be found in different kinds, consisting of portable and stationary models, satisfying various work space needs and project needs. The convenience of the planer permits woodworkers to deal with a variety of tasks, from great furnishings making to large-scale kitchen cabinetry. Normal upkeep, such as blade sharpening and cleaning, is critical for peak efficiency and long life. Inevitably, the planer is an essential possession in any woodworking shop, equipping artisans to attain professional-quality outcomes regularly.

Jointers: Perfecting Wood Edges for Seamless Joints

Jointers play a vital role in woodworking by making certain that sides are completely lined up for seamless joints. Various types of jointers accommodate different demands and choices among artisans, each offering one-of-a-kind attributes and capacities. Appropriate maintenance of these machines is important for achieving peak performance and long life.

Kinds of Jointers

Precision is essential in woodworking, especially when it concerns achieving smooth joints. Jointers been available in numerous kinds, each developed to meet details requirements and preferences of craftsmen. One of the most typical kind is the standard jointer, including a flat table and a cutter head that enables effective edge flattening. For those calling for transportability, the benchtop jointer uses a small solution without giving up performance. The bigger, commercial jointers provide boosted power and effectiveness, making them appropriate for high-volume jobs. In addition, spiral jointers include helical cutter check these guys out heads that reduce tear-out and supply smoother finishes. Recognizing the different kinds of jointers allows craftsmen to pick the right devices for their tasks, making sure precision and top quality in every joint.

Jointers Upkeep Tips

How can artisans guarantee the durability and efficiency of their jointers? Routine upkeep is essential. Initially, they should maintain the jointer tidy, removing sawdust and debris that can impact efficiency. Monitoring and adjusting the blades for sharpness is important, as boring blades can bring about bad cuts. Craftsmen should additionally inspect the infeed and outfeed tables for monotony, ensuring they are aligned effectively. Lubing relocating components assists keep smooth operation and minimizes wear. In addition, it is advisable to periodically examine the motor and electric parts for any signs of wear or damage. Ultimately, keeping the jointer in a completely dry atmosphere secures it from corrosion and deterioration, additional prolonging its life expectancy and preserving its precision.

Dirt Collection System: Preserving a Tidy Office

Numerous alternatives are readily available, ranging from mobile dirt enthusiasts to central systems that link to several equipments. Choosing the right system depends on the scale of the workshop and the kinds of equipment utilized - Wood Glue Applicators. Routine upkeep, such as checking and cleansing filters for clogs, warranties peak performance

Frequently Asked Questions

What Safety Tools Do I Required for Woodworking Machinery?

To guarantee safety while making use of woodworking machinery, people must use safety goggles, ear protection, dirt masks, and handwear covers. In addition, an initial aid kit and fire extinguisher ought to be easily easily accessible in the workshop.

How Do I Maintain My Woodworking Machinery for Long Life?

Regular upkeep of woodworking machinery involves cleaning, lubricating relocating components, looking for wear, and tightening up loosened components. Following supplier guidelines and scheduling routine evaluations guarantees peak performance and expands the lifespan of the equipment.

What Kinds of Wood Are Ideal for Beginners?

Softwoods like want, cedar, and fir are perfect for novices due to their workability and cost. These timbers are much easier to cut, shape, and surface, making them perfect for first woodworking projects and ability advancement.

Can I Utilize Woodworking Machinery for Other Products?

Yes, woodworking machinery can be used for various other materials such as plastics, compounds, and soft steels. It's important to adjust setups and tools appropriately to assure peak performance and avoid damages to both equipment and products.

Just how Do I Choose the Right Blade for My Saw?

Choosing the right blade for a saw entails considering product kind, density, and preferred cut surface. Blade teeth count and geometry also her explanation play crucial functions, guaranteeing peak performance for details woodworking or cutting jobs.

Miter saws supply artisans with the ability to make specific angled cuts with ease, an essential element for lots of woodworking projects. Band saws are a staple in woodworking, supplying an impressive range of reducing capabilities that cater to numerous jobs. The upright band saw is excellent for complex cuts and resawing, allowing woodworkers to develop curved forms and specific joints. These equipments excel in making straight cuts, rounded cuts, and intricate forms, which makes them crucial for different woodworking projects. Ensuring the band saw is kept in a completely dry atmosphere shields it from rust and deterioration, making it ready for precision reducing whenever required.